. Engineering and Contracting . iles of new roadway, aia cost of $94,404. (6) Engineering and Contracting for January 7, 1920. Method of Resurfacing Worn Brick Pavement With Asphalt By CHARLES E. MURPHY,The Texas Co.. New York. Perhaps no other section of the country has attained moresuccess in resurfacing worn brick pavements with asphaltthan has been accomplished throughout the states of themiddle west. Topeka and Wichita in Kansas; Kansas City.St. Joseph and St. Louis, Mo.; Lincoln and Beatrice in Ne-braska, and Fort Smith in Arkansas, are among the citieswhich have successfully treated the

Image details

Contributor:

Reading Room 2020 / Alamy Stock PhotoImage ID:

2CE7BJKFile size:

7.2 MB (192 KB Compressed download)Releases:

Model - no | Property - noDo I need a release?Dimensions:

3107 x 805 px | 26.3 x 6.8 cm | 10.4 x 2.7 inches | 300dpiMore information:

This image is a public domain image, which means either that copyright has expired in the image or the copyright holder has waived their copyright. Alamy charges you a fee for access to the high resolution copy of the image.

This image could have imperfections as it’s either historical or reportage.

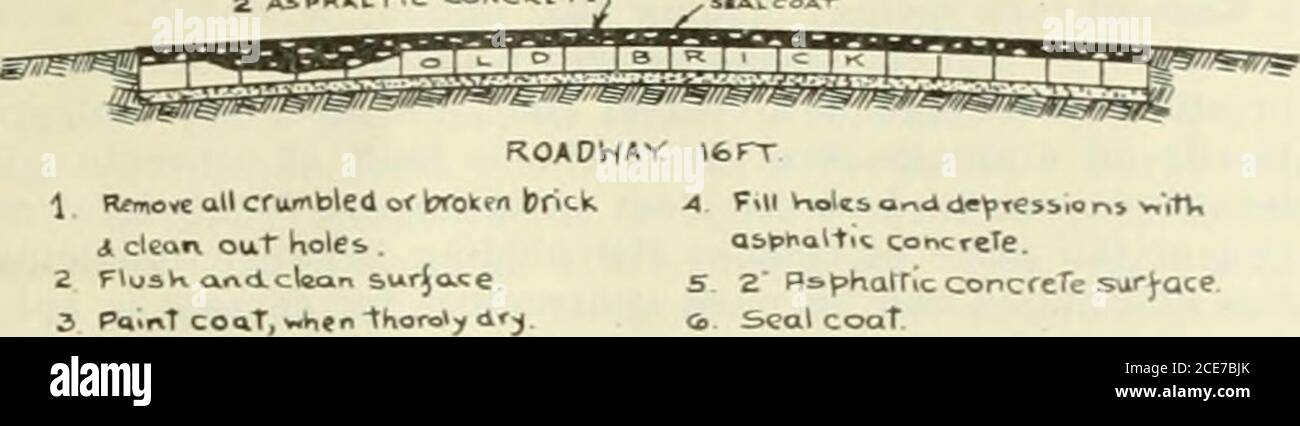

. Engineering and Contracting . iles of new roadway, aia cost of $94, 404. (6) Engineering and Contracting for January 7, 1920. Method of Resurfacing Worn Brick Pavement With Asphalt By CHARLES E. MURPHY, The Texas Co.. New York. Perhaps no other section of the country has attained moresuccess in resurfacing worn brick pavements with asphaltthan has been accomplished throughout the states of themiddle west. Topeka and Wichita in Kansas; Kansas City.St. Joseph and St. Louis, Mo.; Lincoln and Beatrice in Ne-braska, and Fort Smith in Arkansas, are among the citieswhich have successfully treated their worn brick pavementswith either sheet asphalt or asphaltic concrete wearing sur-face. Many of the older brick streets are paved with brick inferior in quality to the brick being used today. Under traifie some of these old brick pavements have worn badly and form thickness in wearing surface to be laid. After that, lay a wearing surface of either asphaltic concrete or sheetasphalt, at approximately 2 in. in finished thickness.. Cross Section Showing Methods of Applying 2-ln. AsphalticConcrete. have become rough. An economic survey of conditions hasrevealed the fact that much of the original investment maybe saved to the property owners by utilizing the worn brickpavements as a base for an asphaltic wearing surface. On account of the fact that it is not necessary to use anexcessive depth for an asphaltic wearing surface, drainageproblems and surface conditions usually are met easily. Thework of laying an asphaltic w-earing surface can be done rap-idly, and on important traffic thoroughfares the work maybe carried out without excluding the traffic from the street, by simply laying the surface on one side of the street andconfining the traffic on the other side. When the one side hasengineeringcontr53chicuoft