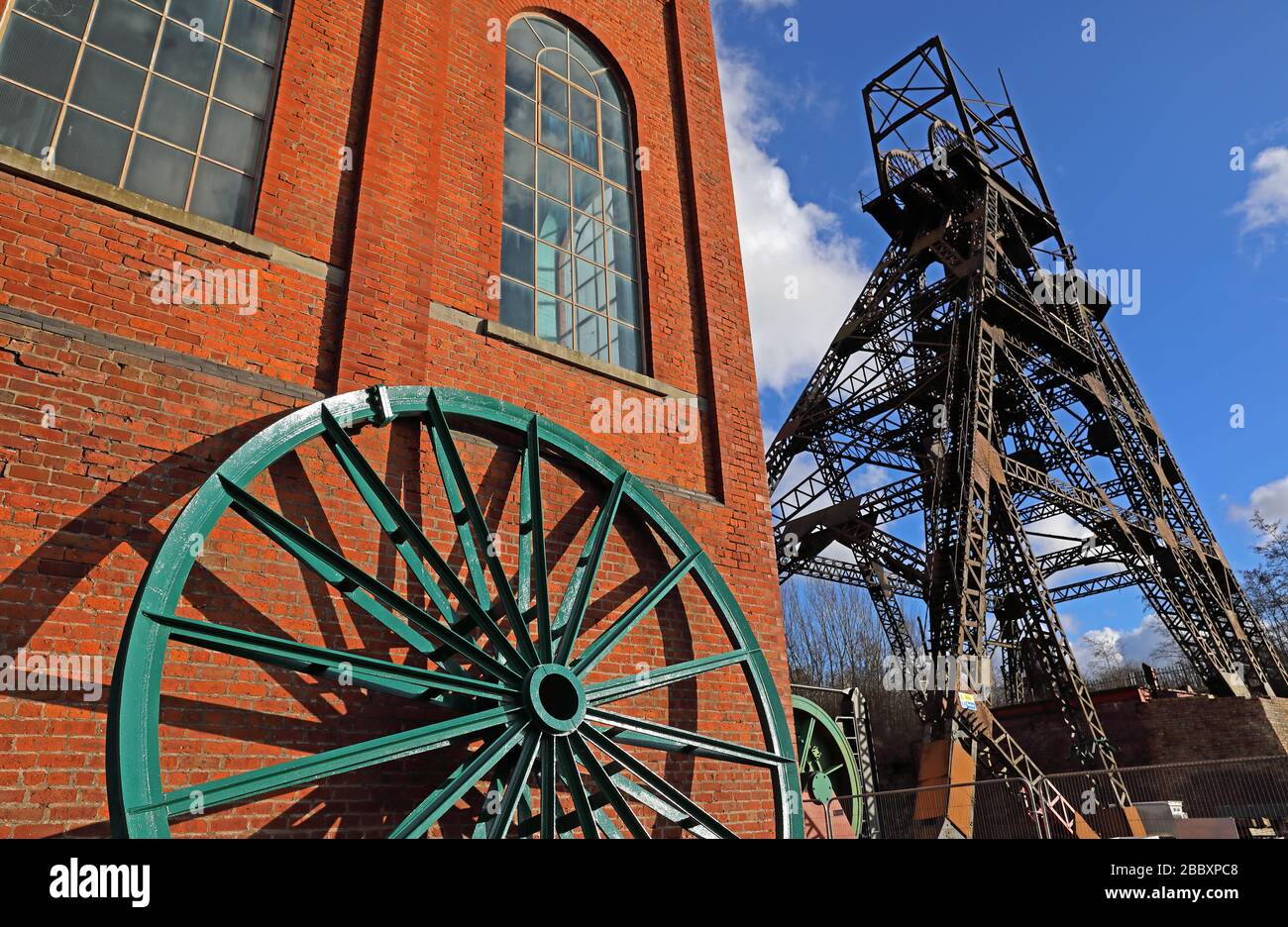

Winding Gear and Pit Head, Coal mine, Colliery and museum, Astley green, Manchester, Lancashire, North West England, UK

Image details

Contributor:

Tony Smith / Alamy Stock PhotoImage ID:

2BBXPC8File size:

84.1 MB (4 MB Compressed download)Releases:

Model - no | Property - noDo I need a release?Dimensions:

6720 x 4376 px | 56.9 x 37.1 cm | 22.4 x 14.6 inches | 300dpiDate taken:

10 February 2019Location:

Lancashire Mining Museum Higher Green Lane Astley, Manchester, Lancs, England, Uk, M29 7JBMore information:

Astley Green Colliery was a coal mine in Astley, Greater Manchester, then in the historic county of Lancashire, England. It was the last colliery to be sunk in Astley. Sinking commenced in 1908 by the Pilkington Colliery Company, a subsidiary of the Clifton and Kersley Coal Company, at the southern edge of the Manchester Coalfield, working the Middle Coal Measures where they dipped under the Permian age rocks under Chat Moss. The colliery was north of the Bridgewater Canal. In 1929 it became part of Manchester Collieries, and in 1947 was nationalised and integrated into the National Coal Board. It closed in 1970, and is now Astley Green Colliery Museum. No 1 pit was sunk to 890 yards primarily to win coal from the Trencherbone mine and No 2 pit was 833 yards deep. The shaft was 23 feet in diameter. The Crombouke and Rams mines were intersected by the sinkings. Firedamp was a problem in the new workings and ventilation was a problem. The headgear of No.1 pit survives, it is made from wrought iron lattice girders with riveted plates at the joints and one small and two large wheels mounted at the top. It is nearly 30 metres (98 ft) high and was built by Head Wrightson of Stockton-on-Tees and completed by 1912. In 1912 a twin tandem compound 3300 horsepower winding engine built by Yates and Thom of Blackburn, the largest ever used on the Lancashire Coalfield, was installed at No 1 pit. The company built a smaller cross compound winding engine for No 2 pit, installed in 1919. In 1923 the colliery employed 1524 men underground and 436 surface workers; which increased to 1631 underground and 492 surface workers by 1933. At Nationalisation in 1947 the colliery employed 1375 below and 561 above ground. The surface workers included women, known as pit brow lasses, who sorted coal on the screens. Women were employed at Astley Green until the mid-1950s.